ตะกร้าสินค้าของคุณว่างเปล่า!

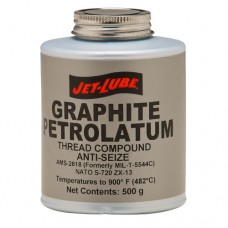

JET-LUBE : GRAPHITE PETROLATUM

ราคา: 0.00บาท

ไม่รวมภาษี: 0.00บาท

ไม่รวมภาษี: 0.00บาท

จำนวน:

BENEFITS:

- Retains the equipment in serviceable condition.

- Environmentally preferred anti-seize lubricant.

- Prevents seizing during the assembly or disassembly of aircraft engine spark plugs and threaded fasteners and fittings.

- It is suitable for contact with austenitic steels(non-magnetic steel), titanium, nickel and cobalt alloys, and other similar corrosion resistant metals and alloys.

- Has controlled frictional characteristics so that the surfaces of the Nut & Bolt are torque to the designed K-Factor.

- Assures full hydraulic efficiency by allowing the metal surfaces to slide over each other without metal-to-metal contact.

DESIGNED FOR:

Specially formulated to prevent excessive over torque issues and has a very high static friction factor of 0.13, the unique blend of complex thickeners to help evenly distribute the copper flake unto the metal surfaces to eliminate metal to threaded metal contact.

RECOMMENDED APPLICATION:

- Stud threads shall be thoroughly lubricated on both ends, fill the threaded area “Root – to – Crest” on the stud/bolt. The nut will push the anti- seize down the threads as it travels.

- Bearing surfaces between nut and hardened washer or nut and flange should be lubricated with anti -seize in the area where the nut will rest against the flange or washer.

- Anti -seize on the assembly should be easily visible.

NOT RECOMMENDED FOR:

Oxygen service

เขียนข้อคิดเห็น

พิมพ์รหัสป้องกันสแปม: